Original Relationship Established

We were approached alongside BCS Hydraulics to look at performing Ravestein lock gate repairs and reactive maintenance on the vast & complex Ravestein lock gate infrastructure at Grimsby Docks. Following many technical repairs and significant improvements, we created a maintenance program that involves technical maintenance, utilising the wonderful on-site team of Lock Keepers for regular ownership style small repairs & checks. We run a regular inspection and engineering maintenance schedule throughout the year to keep the gates in operation for Grimsby Enterprises, which oversees marine access control for Grimsby’s busiest lock gates, assisting the fishing and offshore industry.

Reactive Marine Infrastructure Repairs

Upon inspection of the Grimsby fish dock infrastructure, we found the shoot bolt wedge had come loose, meaning the shoot bolt couldn’t fully go down. The wedge blocks are bolted underwater to the framework of the flood gate infrastructure. The system allows the flood gates to be opened the opposite way, allowing larger vessels to be penned into the docks. Our engineers have undergone extensive training to perform Ravestein marine maintenance and repairs, who are the designers of this floodgate system.

The lock gate infrastructure is vital to Grimsby Enterprises operations. Without the fully-functioning lock gate system, larger pens cannot be performed which are vital to wind farm maintenance teams surrounding the Humber estuary. Based in Immingham Docks, Hickman Engineering are able to provide reactive repairs to equipment in the Immingham and Humber regions, as well as areas further afield. Our reactive repair services enabled us to provide efficient lock gate repairs and maintenance to Grimsby Enterprises’ lock gates, reducing machine downtime and allowing operations to continue as soon as possible.

The Lock Gate Repairs and Maintenance

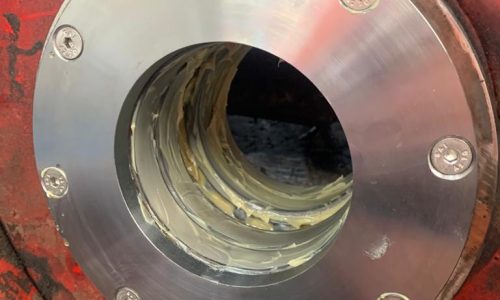

The wedge blocks are bolted to a piece of framework at the dock bottom. When the gates come to the sill, another wedge inside the gate moves down under hydraulic pressure, fitting the bolted wedge to the framework and keeping the bottom of the gate tight against the sill.

This particular job was carried out by Shaun Polley and Garrick Hickman. Hickman Engineering also partnered with underwater engineers from Northern Divers, based in Hull, who carried out the marine maintenance of the port equipment underwater. Our lathe and milling machine was vital in this project, with a thermal lance and hydraulic drill being used for the underwater sections of the project.

The project took approximately two weeks from the initial assessment, design and correspondence, finalisation of engineering procedures, communication and toolbox talks, through to the installation itself and testing. With the project being a specialist job, a large degree of knowledge was required, as well as foresight and sensitivity to the client’s budgetary stipulations and limitations.

“We run a year from year maintenance program with fish dock enterprises, which is all planned in. Any major works will get discussed and a plan would be made on how we would carry out the task with minimal disruption to the operation of the lock gates.

Coming up with a better idea of keeping these wedge blocks in place while making it easier for the divers to fit was a challenge, but we always come up with a solution to solve the problem.

All parties that were involved in this job were very happy with the outcome & had full confidence it would provide a long term solution.”

– Shaun Polley, Hickman Engineering

What Grimsby Enterprises Say

‘We have a wonderful relationship with Hickman Engineering and especially Shaun & Garrick. We have total trust in them and that they really care about us.

Only the Hickman Engineering lads know our gear and its quirks. An outsider would almost certainly run into problems or dead ends. We are very pleased that the work was done so efficiently, cleanly and we are back up to full capacity with no closure required. Perfect!

Without a doubt, we would recommend Hickman Engineering. Their slogan is ‘we never shy away’ and this is very apt and true.’

– Ian, Grimsby Enterprises