Thanet District Council recently contracted Hickman Engineering for a Lock Establishment Project, specifically focusing on the Flap Gate Marine Infrastructure. This infrastructure is integral to the main lock facility of the client’s marina as it is used daily to operate the lock gates, so it is critical to the operational requirement of the client.

Assessing the Repair

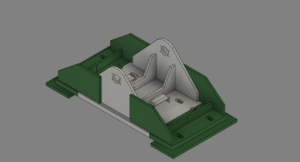

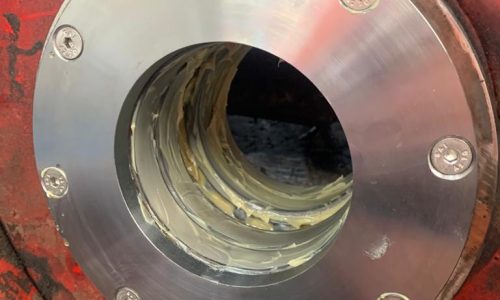

Initially we were tasked with repairing a supporting bracket for one of the main hydraulic arms. This bracket had been torn from its foundations. After discussions and structural assessments, it was decided to modify the bracket for improved longevity. Hickman Engineering’s in-house CAD team designed the modifications, which were then fabricated and installed by various divisions within the company. Additionally, measures were taken to prevent flooding during the repair process.

We met key dates for the duration of the lock establishment project, completing the works within the scheduled time due to the dedication and experience of our staff. The project was highly specialised, requiring the expertise of multiple divisions within Hickman Engineering, including CAD design, welding, fabrication, machining, engineering, and accredited diving teams. The work involved a comprehensive overhaul of critical infrastructure, with multiple staff members from all divisions within our business, as well as third-party providers from our accredited contractors list, engaged to complete this project.

Completing the Engineering Project

To accomplish the lock establishment work, a range of tools and equipment were employed.This included CAD Design software, welding generators, stick welders, MPI (Magnetic Particle Inspection) testing equipment, cylinder testing tools, a 40-ton crane, a lathe, and a burning torch. This was a custom job due to the nature and location of the bracket assembly. Though we carry out similar engineering works, the surveyor’s stringent processes had to be adhered to, to ensure that the repair and modification were conducted to the highest standards.

After the lock establishment work was completed, one of our team commented:

“We often work on equipment like this, however due to the nature of the task this was deemed a custom job. The job itself had its challenges, however with our dedicated divisions we were able to overcome unforeseen challenges. We are extremely satisfied with the work carried out. We pride ourselves on developing, fabricating and installing a product that will stand the test of time.”

Lock Establishment Specialists

Our client identified the need to bring Hickman Engineering in as specialists for this lock establishment project:

“Initially the project was undertaken by council teams, but due to the specialist nature of the facility, the engineering and risks involved, it was appropriate to engage a specialist to manage the project. We commenced a procurement exercise and awarded the works to Hickman Engineering. Through the process we saw their success on a similar project in Grimsby, and after awarding the works invited them to a site visit to review our project.”

Happy with the service that we provided, they continued:

“Due to the high profile nature of the asset and the risks involved, engaging engineering specialists ensured the management and repairs would be carried out to a high standard. Hickman Engineering maintained a very high standard throughout, providing us with regular progress updates, keeping us informed of costs and expenditures and liaising with us throughout. We would recommend Hickman Engineering to others.”

If you have a similar project in need of engineering specialists, or for any of your engineering needs, please contact us today.