Hickman Engineering has forged a long-standing relationship with Casper Shipping, having completed a variety of projects for them and continuing to do so to this day. Our commitment to 24/7 service including custom fabrication at a fixed rate ensures a rapid and efficient response to our client’s evolving needs and challenges.

One of our recent projects for Casper Shipping involved the meticulous design and custom fabrication of a pedestal bracket bespoke to the customer’s exact specifications. This custom fabrication endeavour was crucial, as it played a pivotal role in securely holding an Emergency Position Indicating Radio Beacon (EPIRB). The precision and accuracy in crafting this equipment were paramount, considering its crucial function and the necessity for additional attachments to be seamlessly integrated.

Casper Shipping heavily relies on this specific piece of equipment for safe and efficient operations. The equipment’s critical role underscores the importance of the customised solution we provided and its vital contribution to Casper Shipping’s overarching safety protocols.

Scope of the Custom Fabrication Work

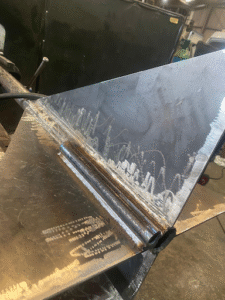

The project required the involvement of our in-house CAD design team, which created a precise design that aligned with our client’s requirements. Once the design received approval, our adept welding and fabrication division took charge, translating the design into a tangible, functional product. This project showcased our versatile capabilities, clearly demonstrating our capacity to design and fabricate products of varying sizes and quantities while maintaining exacting standards.

This project represented a specialist custom job, an area where we excel. The work was expertly carried out by Max Burton and Kameron Cullen, utilising a range of specialised tools, including CAD design software, welding equipment, grinders, a cutting torch, and an overhead crane, to ensure the project’s swift and precise completion. The work was accomplished within seven hours, underscoring our dedication to efficiency and the adherence to deadlines, qualities that we are proud of.

Reflecting on the project, Max and Kameron said, “The custom fabrication job itself was not challenging, however it meant that our CAD Design team had to start from scratch to create a drawing which suited the clients requirements. Once this had been confirmed it took little time for our Welding and Fabrication division to fabricate this item”.

Casper Shipping expressed immense satisfaction with Hickman Engineering’s work on this project, stating, “Hickman Engineering has successfully executed numerous fabrication projects for us. Their prompt responsiveness and reliability make them our unequivocal choice.”

The ongoing partnership between Hickman Engineering and Casper Shipping epitomises our dedication to delivering tailored solutions, technical expertise, and timely service to meet the unique requirements of our clients in the maritime industry.

For all your custom design and fabrication needs, please contact us for a free quote.