Jack Charrington Pratt

Discovering Running Issues

Mr Jack Charrington Pratt, a Model Maker, Lecturer and Concept Artist, called us as a new customer following his purchase of a vessel named the Swan Song. Whilst the vessel was being delivered to Hartlepool, the client’s port of choice, the delivery skipper encountered running issues and decided to take refuge in Grimsby. As the boat was moored at Humber Cruising Association, Jack engaged our boat repair and maintenance services to investigate the running issues, (blue smoking and using oil).

At this stage, it was agreed that Port Equipment Engineering would perform diagnostic tests on the original BUKH marine engine. The procedures carried out were performed on a fixed price quotation basis.

Identifying The Root Cause

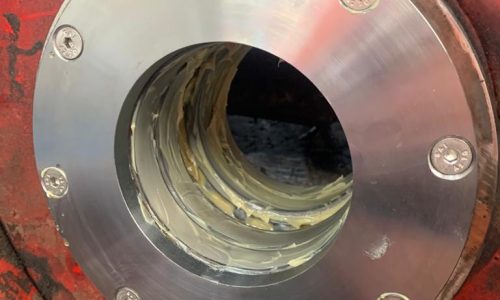

Having arrived on site at the marina we turned on the sea valve, isolator, fuel, and ran the vessel’s engine. Upon running the engine, we discovered a large amount of blue smoke from the exhaust which we suspected was either the valve stem seals or pistons/liners. In order to investigate the issue further, our team of engineers removed the injectors and the injector collar from the cylinder head. Using our fabricated compression tester adaptor, we were able to carry out a compression test on each cylinder allowing us to diagnose if the pistons/liners or the valve stem seals were at fault. Results from the compression test indicated that the pistons and /or liners were worn.

The vessel’s engine was returned to our workshop having been lifted from the boat with a hoist and loaded into one of our mobile workshop vehicles. We performed a parts and labour study for the engine dismantlement and presented it to the client. A fixed price was then agreed upon. At this stage, we offered the client both an engine repair option or an option to supply a BETA 25 marine engine from Beta Marine. The client opted to have a new Beta Marine engine installed, so an order for the BETA 25 engine was immediately placed.

Installation

Aligning a different manufacturer of engine onto the vessel’s original engine bed has its challenges. Bespoke mountings for the engine and gearbox had to be designed and fabricated allowing both units to be secure as well as aligning with the propeller shaft. Alterations were also made to the wet exhaust system, seawater intake pipework, feed and return fuel lines, new morse control cables, positive and negative battery cables to the starter motor and fitment of an anti syphon device because the engine sits below the water line. A standard control panel was also supplied with the Beta 25 engine. Fabrication works were carried out introducing the new control panel within the original dashboard of the vessel, including extension of the wiring loom.

Boat Repairs in Lockdown

By this point, the UK was in a full lockdown, we at Port Equipment Engineering were focused on engaging work that could be delivered to our premises alleviating restrictions. Unfortunately, this meant the Swan Song’s repairs had to wait until our national lockdown restrictions began to ease before they could continue. We were acutely aware that the Swan Song was a major purchase for our client and he was dependent on the vessel as it would become his home & business base. Given that he couldn’t even travel to his new vessel due to lockdown restrictions, we put strategically timed contact in place.

Requiring a specially modified engine tripod carrier and an on-site hoist, this was a very unique project which brought with it many time-related challenges. When the decision was made to use the new BETA 25 engine unit for the project, the UK was in full lockdown as well as learning how to cope with its exit from the European Union. With the lockdown restrictions and slow arrival of the new motor, the project as a whole took approximately 6 months to complete, with the full installation taking around 100 hours of labour.

Specialists in Marine Equipment

The project was a specialist marine task and due to the many items that could be an issue when marinising port equipment, having the intuition, foresight, and experience in marine/boat repairs and maintenance is essential when it comes to performing work on small vessels. Matthew Balderson, Senior Technical Engineer for marine equipment, was a key part of the work we carried out on the Swan Song. At Port Equipment Engineering we are always very satisfied with Matthew’s work on various projects.

His comments on the project are as follows:

“Due to our ideal location & strong road network, we provide round-the-clock support to vessels small and large. Every yacht installation is different & presents its own challenges. This one had particularly tricky engine alignment issues to overcome.”